For decades, modern construction has depended heavily on cement and concrete. They build our homes, roads, bridges, and cities but they also come with a serious environmental cost. Cement production alone contributes roughly 7–8% of global carbon dioxide emissions, and experts agree those numbers must drop quickly if climate targets are to be achieved.

That’s why researchers have started looking beyond traditional raw materials. One solution gaining real attention is the low-impact building material from crushed seashells. Instead of mining fresh limestone or river sand, scientists are turning to ocean waste to produce durable construction components. This low-impact building material from crushed seashells offers a rare combination: sustainability, practicality, and scalability. The idea solves more than one problem at a time. Coastal seafood industries generate millions of tons of shells every year. Restaurants, fisheries, and processing plants usually dump them into landfills where they create odor and environmental management issues. Repurposing shells into construction material converts a disposal challenge into a useful resource. At the same time, it helps reduce mining and lowers the carbon footprint of building projects.

The concept behind the low-impact building material from crushed seashells is surprisingly logical. Seashells consist mainly of calcium carbonate, the same mineral that makes up limestone, the primary ingredient of cement. Scientists clean, crush, and grind discarded shells into fine powder or coarse aggregate. They then combine the particles with alternative binders that require far less energy than traditional cement production. The finished material can be molded into bricks, wall panels, paving blocks, and other construction elements. Researchers have also found that shell-based composites naturally resist moisture and salt damage, which makes them especially promising for coastal environments and humid climates.

Table of Contents

Low-Impact Building Material from Crushed Seashells

| Key Feature | Details |

|---|---|

| Raw Material | Oyster, clam, and mussel shells |

| Chemical Composition | Calcium carbonate |

| Manufacturing Process | Cleaning, grinding, mixing with low-carbon binder |

| Environmental Impact | Reduces landfill waste and CO₂ emissions |

| Strength | Comparable to lightweight concrete |

| Main Uses | Bricks, tiles, panels, pavements |

| Energy Consumption | Lower than traditional cement production |

| Sustainability Model | Circular economy construction material |

As urban populations grow, construction will continue to expand. The real challenge is building responsibly. The low-impact building material from crushed seashells demonstrates that innovation does not always require inventing something entirely new. Sometimes it means recognizing the value hidden in what we throw away. By turning marine waste into useful infrastructure, scientists are opening a practical path toward cleaner, more sustainable construction for the future.

Why Seashells Work as A Construction Material

- At first, the idea sounds almost too simple. How can something as ordinary as a shell help build a house? The answer lies in biology. Marine organisms spend their entire lives building shells that protect them from predators, pressure, and ocean currents. Over time, nature developed a structure that balances strength and flexibility better than many artificial materials.

- Under a microscope, shells reveal layered crystal formations arranged in repeating patterns. These layers prevent cracks from spreading easily. When shells are crushed and mixed into construction material, the particles interlock tightly, improving internal bonding. Instead of smooth sand grains sliding against each other, jagged shell fragments grip the mixture together.

- Availability also makes them attractive. Coastal regions generate massive shell waste every day. Rather than transporting waste to landfills, processing it locally into the low-impact building material from crushed seashells creates a new resource stream while reducing transportation emissions.

How The Material Is Made

- The production process is straightforward and adaptable to existing manufacturing systems. It does not require complicated machinery, which is part of why the idea is gaining serious interest.

- The first step is collection. Shells are gathered from seafood markets, aquaculture farms, and food processing facilities. After collection, they undergo thorough washing to remove organic matter. This step prevents unpleasant odors and bacterial growth.

- Next comes drying and crushing. The shells are dried completely and ground into different sizes. Coarser pieces act as aggregate similar to gravel, while finely powdered shells act as filler material.

- The critical step is mixing. Instead of using traditional Portland cement, engineers blend shell particles with low-carbon binders such as geopolymers or magnesium-based compounds. These materials cure through chemical reactions instead of high-temperature heating. That means far less fuel consumption and significantly fewer emissions.

- Finally, the mixture is molded into bricks, tiles, or panels and left to cure. Once hardened, the product becomes a usable low-impact building material from crushed seashells ready for construction.

Performance And Durability

- Strength testing was one of the earliest priorities. Engineers cannot recommend a material unless it performs reliably under pressure. Laboratory tests show shell-based materials hold compressive loads comparable to lightweight concrete, making them suitable for residential and low-rise construction. Durability results are especially encouraging. Because shells formed in seawater, they naturally tolerate moisture and salt exposure. This makes the material resistant to corrosion and weathering in coastal areas where ordinary concrete often deteriorates faster.

- Thermal insulation is another benefit. Shell composites trap small air pockets inside the material, slowing heat transfer. Buildings made with the low-impact building material from crushed seashells can stay cooler in warm climates, reducing dependence on air conditioning and lowering energy bills. Shrinkage cracking, a common issue with concrete, is also reduced. The shell particles help distribute internal stress more evenly, preventing the formation of large fractures over time.

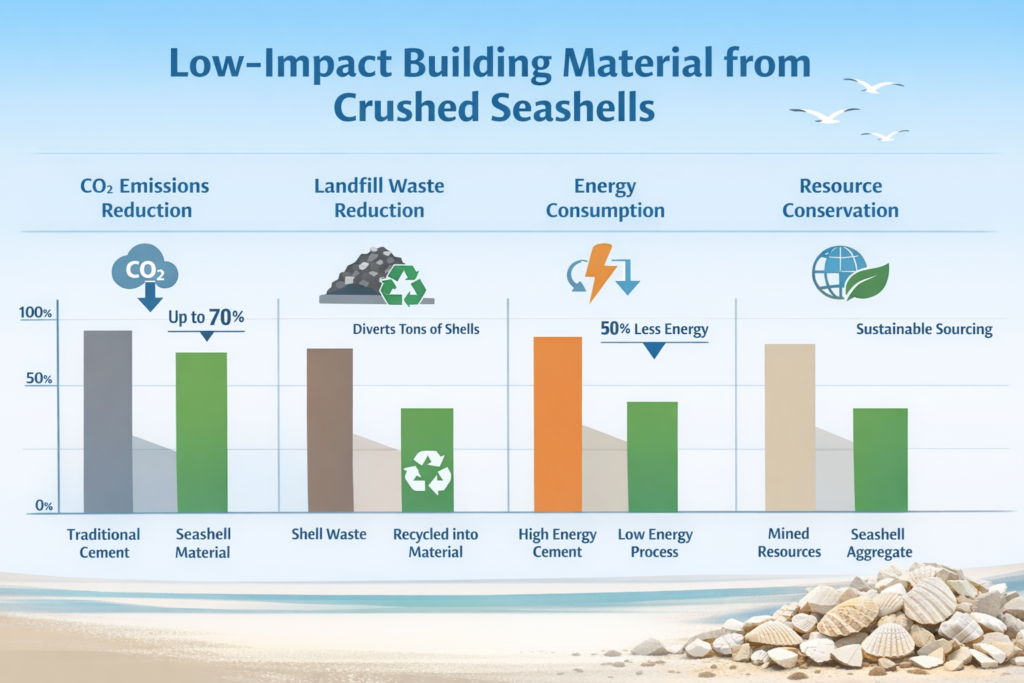

Environmental Benefits

- The environmental advantages are the main reason researchers are investing time into this innovation. Traditional cement manufacturing requires heating limestone to extremely high temperatures, releasing carbon dioxide both from fuel combustion and chemical reactions.

- By contrast, the shell-based approach avoids much of that process. Since shells already contain calcium carbonate in a natural form, they do not require the same intense heating. The low-impact building material from crushed seashells therefore produces far fewer emissions during production.

- The sustainability benefits include reduced greenhouse gas output, less river sand extraction, decreased limestone mining, and lower landfill waste. It also supports a circular economy. Instead of extracting new raw materials, industries reuse what was once considered trash.

- For coastal communities, the impact could be significant. Shell piles often accumulate near fishing ports and processing plants. Converting them into building materials creates jobs while improving local environmental conditions.

Potential Applications

- This material is not limited to one construction use. Researchers are testing multiple applications across the building sector. Residential housing is the most immediate opportunity. Lightweight blocks and prefabricated panels make construction faster and easier. Interior partition walls, non-load-bearing structures, and insulation boards are also suitable. Paving and landscaping are promising uses as well. Sidewalks, garden paths, and outdoor tiles benefit from the durability and salt resistance of the low-impact building material from crushed seashells.

- Coastal infrastructure may ultimately see the greatest benefit. Sea-facing structures such as promenades, marina walkways, and waterfront barriers require materials that resist salt corrosion. Shell-based composites naturally perform well in those conditions. Architects have also shown interest in its appearance. The material often displays a subtle natural texture, giving buildings a distinctive finish without additional coatings.

Challenges And Next Steps

Despite strong results, challenges remain before large-scale adoption. Not all shells are identical. Different species produce varying thickness and mineral composition, so standardizing quality is necessary. Building regulations present another hurdle. Construction materials must pass strict long-term safety testing before widespread approval. Engineers are conducting durability studies to evaluate how the low-impact building material from crushed seashells performs over decades. Supply logistics also need coordination. Efficient systems must connect seafood processors with manufacturing plants to ensure steady production. However, progress continues. Pilot housing projects and small commercial structures are already being tested, and interest from sustainable developers is growing quickly.

FAQs on Low-Impact Building Material from Crushed Seashells

What Makes Seashells Suitable for Construction?

Seashells are rich in calcium carbonate; the same mineral used in cement. Their layered microstructure provides natural strength and crack resistance when processed into building materials.

Is This Material Cheaper Than Concrete?

Costs vary by region, but using recycled waste can reduce raw material expenses, especially in coastal areas with abundant shell supply.

Can It Be Used in Large Buildings?

Currently, it is best suited for low-rise buildings, panels, pavements, and non-load-bearing elements. Research is ongoing for heavier structural use.

Does It Really Help the Environment?

Yes. It reduces landfill waste and lowers carbon emissions by minimizing the high-temperature processes required for traditional cement.