Imagine walking into a pyramid chamber and realizing the smooth granite blocks surrounding you were shaped thousands of years before electricity existed. That single moment changes how you think about history. It’s the reason historians and engineers still debate Ancient Egyptian advanced drilling technology today.

The precision inside Egyptian monuments is not random, and the tool marks found in stone show careful planning, not guesswork. In fact, Ancient Egyptian advanced drilling technology suggests these craftsmen understood mechanical processes far better than we once believed. For generations, people pictured pyramid builders as laborers hammering endlessly on rock with primitive tools. But archaeological discoveries over the last century have challenged that idea. Carefully studied drill holes, stone cores, and carved vessels reveal consistent patterns created by rotating motion and abrasive cutting. These were not accidental results. They required control, patience, and technical knowledge passed down from master craftsmen to apprentices.

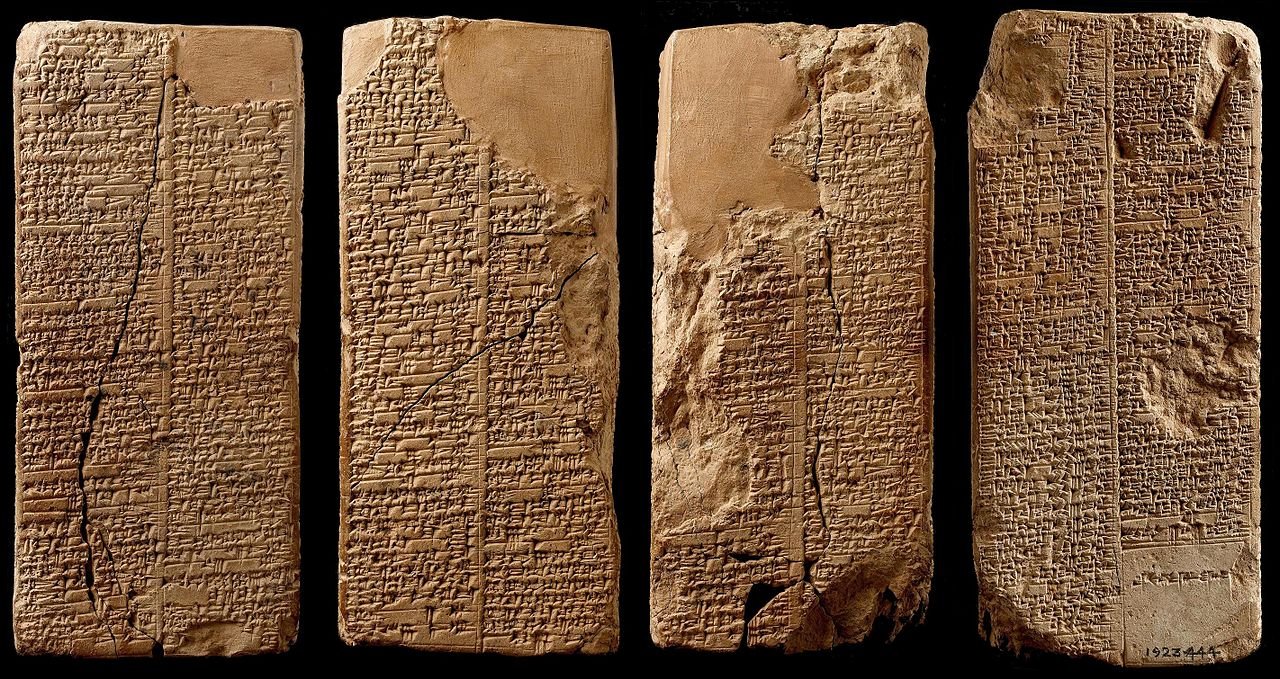

The term Ancient Egyptian advanced drilling technology refers to a collection of stone-working techniques used around 3000 BCE during Egypt’s early dynastic and Old Kingdom periods. Workers used copper tube drills, bow-powered rotation, and quartz sand abrasives to cut extremely hard materials such as granite and diorite. Spiral grooves inside drill holes confirm a steady rotating tool was applied while pressure pushed the drill downward. This method explains how builders shaped sarcophagi, temple stones, and pyramid casing blocks with impressive accuracy. It also helps archaeologists understand how large projects could be completed within a realistic timeframe using organized labor and practical engineering knowledge.

Table of Contents

Ancient Egyptian Toolmakers Used Advanced Drilling Technology

| Feature | Evidence Found | What It Suggests |

|---|---|---|

| Spiral grooves in drilled holes | Inside granite blocks | Rotational drilling |

| Stone cores | Found at Giza | Tubular drill usage |

| Quartz residue | Worksite remains | Abrasive cutting |

| Symmetrical stone jars | Burial artifacts | Rotational shaping |

| Deep aligned holes | Temple stones | Measurement and guiding tools |

| Copper drill remains | Workshops | Tool holders for abrasives |

The spiral grooves, hollow drill cores, precision vessels, and abrasive residues all point to a remarkable truth. Egyptian craftsmen possessed a reliable and repeatable method for shaping hard stone. Ancient Egyptian advanced drilling technology allowed them to cut granite, diorite, and basalt with accuracy long before industrial tools existed. Rather than primitive workers, they were skilled technicians. Their understanding of materials and motion enabled construction on a massive scale. The pyramids may draw the most attention, but the small details hidden in drilled holes tell the deeper story. Thousands of years ago, along the Nile, humans developed practical mechanical engineering using simple tools, patience, and observation. Their work continues to challenge modern assumptions about the limits of early technology.

Evidence From Quarry Sites

- One of the clearest proofs of Ancient Egyptian advanced drilling technology comes from the granite quarries at Aswan. Here, workers once cut massive blocks intended for obelisks and temple construction. A famous unfinished obelisk still lies attached to bedrock, abandoned after cracks formed. What makes the site valuable is that it preserves the working process.

- Channels carved into granite are straight and evenly spaced. They look less like rough hammering and more like controlled machining. Nearby, archaeologists discovered drilled holes and cylindrical stone cores. The interior walls of these holes contain spiral grooves, running continuously down the surface.

- Engineers immediately recognized the pattern. A rotating drill pressed into stone produces exactly this mark. Hammer strikes cannot create a spiral groove. Scraping cannot produce evenly spaced circular cuts. Only rotational motion explains the evidence. These findings strongly support the presence of Ancient Egyptian advanced drilling technology in large-scale construction.

The Tubular Drill Method

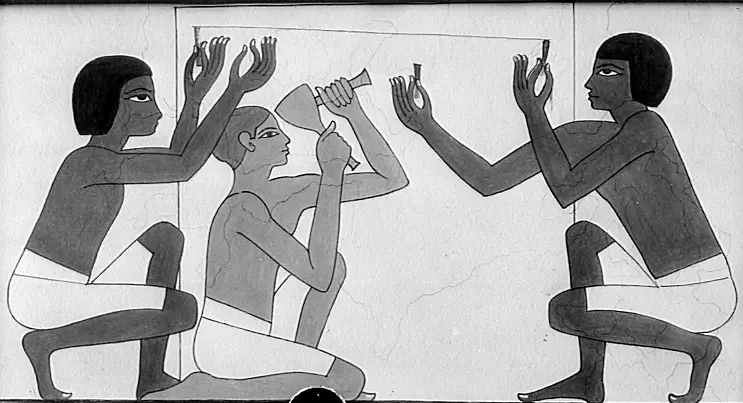

- Egyptian craftsmen used hollow copper tubes instead of solid drill bits. The tube rotated while pressure pushed it downward. Rather than grinding away the entire hole, the drill cut only along the outer edge. The untouched center remained as a stone core.

- This technique was efficient. It required less effort because only a narrow ring of stone needed removal. The cores found at Giza match what modern concrete core drills produce today.

- Copper itself could not cut granite. The real cutting power came from abrasive sand. Workers poured quartz sand between the tube and the stone. As the drill rotated, sand particles ground the granite surface away. The copper acted only as a holder and pressure tool.

- This method demonstrates that Ancient Egyptian advanced drilling technology relied on understanding materials, not just brute strength.

Abrasives: The Real Cutting Tool

- Quartz sand is extremely hard, and Egypt had plenty of it along the Nile River. When trapped between a rotating drill and granite, the grains acted like an industrial grinding compound. Microscopic examination of drill holes shows polishing patterns identical to abrasive machining.

- There are no metal slicing marks. Instead, surfaces appear ground smooth. This confirms Egyptians used stone particles to cut stone.

- This discovery explains a long-standing mystery: how could a civilization without iron tools shape granite statues and sarcophagi? The answer is simple. They did not rely on metal hardness. They relied on abrasive hardness. Understanding this principle was a key part of Ancient Egyptian advanced drilling technology.

Precision Stone Vessels

- Some of the most impressive evidence comes from small artifacts rather than massive monuments. Egyptian tombs contain stone jars carved from basalt and diorite. These materials are extremely difficult to shape even with modern hand tools.

- The vessels are perfectly symmetrical. Their walls are thin and evenly spaced. The interior cavities are centered and smooth. Achieving this requires controlled rotation.

- Researchers believe the stone itself was rotated while an abrasive tool shaped it. Essentially, this functioned like a primitive lathe. Modern craftsmen attempting to replicate these jars using only chisels struggle to match the accuracy. The precision strongly indicates Ancient Egyptian advanced drilling technology was widely practiced in workshops.

Engineering Knowledge And Skill

The technology required practical engineering understanding.

- Controlled Pressure: Workers needed the correct force. Too much pressure would bend copper. Too little would stop cutting.

- Rotational Motion: A bow drill likely powered the tool. A cord wrapped around the shaft allowed rapid spinning when pulled back and forth.

- Material Knowledge: They recognized sand was harder than metal and used it as the cutting medium.

- Alignment And Measurement: Straight holes require guidance. Wooden supports or stone guides probably kept the drill vertical.

These skills show that Ancient Egyptian advanced drilling technology was a trained craft rather than trial and error.

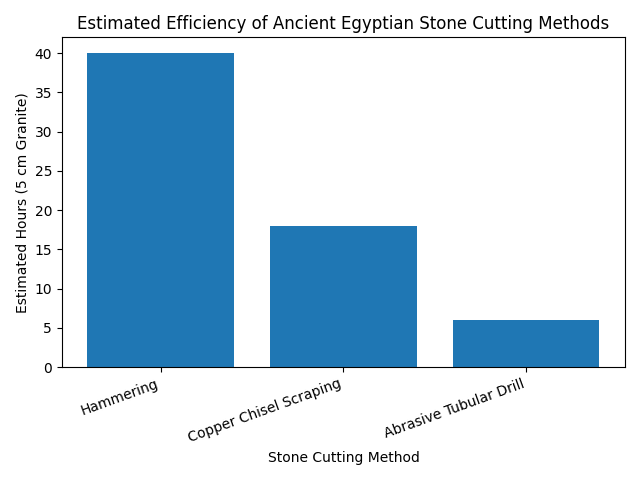

How Fast Were They?

Modern experiments have recreated the ancient process using copper tubes and quartz sand. Researchers successfully drilled granite using only hand power. The process was slower than electric tools but faster than expected. Holes could be drilled within hours. With organized workers, large numbers of blocks could be produced efficiently. This makes pyramid construction timelines more realistic. It also explains how temple construction across Egypt was possible using coordinated teams applying Ancient Egyptian advanced drilling technology over generations.

Rethinking Ancient Technology

For a long time, history books assumed advanced engineering required advanced metals. Egyptian stoneworking proves otherwise. Innovation often comes from understanding natural materials and mechanical motion. The craftsmen were not scientists in the modern sense, yet they practiced applied physics: friction, hardness, and rotational energy. Knowledge passed through workshops allowed steady improvement. The monuments they built were not just artistic achievements. They were engineering accomplishments. Studying them changes how we view ancient civilizations and highlights the sophistication behind Ancient Egyptian advanced drilling technology.

FAQs on Ancient Egyptian Toolmakers Used Advanced Drilling Technology

1. What is Ancient Egyptian advanced drilling technology?

It is a stone-cutting method using rotating copper tube drills and quartz sand abrasives to drill and shape hard stone.

2. How did Egyptians cut granite?

They used abrasive quartz sand between a rotating drill and the stone, allowing grinding rather than slicing.

3. Did Egyptians have mechanical tools?

They used manually powered tools such as bow drills that created rotational motion similar to modern drills.

4. Why are spiral grooves important?

They prove the drill rotated while cutting, confirming a mechanical drilling method.